> Maintenance services

Maintenance services

1.Business philosophy:Use wisdom maintenance service concept, improve operational efficiency equipment for the global construction materials manufacturer.

2. Main business:

Fault remote diagnosis and expert on-site consultation;

Maintenance optimization and construction supervision and management;

Localization maintenance team presence, emergency repairs 7DAY * 24H service.

3. Show of maintenance technology strengths

(1) Rotary kiln maintenance

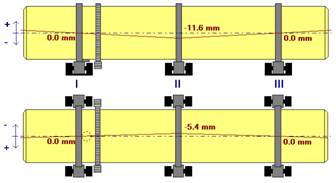

Rotary kiln centerline online measurement, line adjustment.

A、Determination of the rotary kiln axis

B、Determination of kiln shell deformations (shell profile)

C、Determination of the kiln shell ovality (shell test)

Replacement and Polishing work of Kiln tyre, girth gear and bearing of Supporting roller.

(2) Maintenance of large vertical mill

Maintenance of large vertical roller mill’s ATOX, MPS, LM, CK, RMR, MLS, MPF etc, on site replacement of vertical mill’s roller and bearing

Maintenance of large vertical roller mill’s ATOX, MPS, LM, CK, RMR, MLS, MPF etc, on site replacement of vertical mill’s roller and bearing

Vertical roller mill: On line hard facing welding of wear resistant lining board

Roller press :on line and off line hard facing welding of roller

KSW-Process is fully automatic and is capable of performing rebuild and resurface welding to wear parts in place by bringing welding equipment to any mills.

Especially ,table segments can be rebuilt and resurfaced in place so that the working process is remarkably shortened and cost of maintenance is reduced.

The deposit through KSW-Process consists extremely stable and remarkably hard M7C3 type carbides. The deposited carbides, the refore, exhibit remarkable wear resistance.

(4) Masonry of refractory materials within the kiln

Masonry of refractory materials within the kiln, grate cooler and pre-heater.

Ball bearings, Maintenance of dust collector, elevator and all kinds of cooler. Replacement of crusher liner,hammer and Transmission.

4. Maintenance of territorial Country

Saudi Arabia, Ethiopia, Jordan, Iraq, Yemen, Oman

Saudi repair centers: Many large cranes, more than 45 permanent employees from China's, several sets of automatic welding equipment,able to complete the vertical roller mill linings and disc online and offline surfacing,able to roller press rollers online and offline reactors weld.

Ethiopia Repairs: New motor repair factory, several sets of automatic welding equipment, mobile tool room, 30 permanent employees from China.

Iraq Repairs: multiple sets of automatic welding equipment,

Iran, Bangladesh service center: to repair technology export as the main way, a number of technical staff Permanent, maintenance technicians on-site guidance and supervision of the construction program and other services.

In addition to the existing maintenance center permanent staff, ready to send personnel from China totaled more than 100 people.

A number of European equipment / product partner (IKN, Loesche, Thunder), providing high-tech service.

5. Maintenance a list of performance :( outside part of the maintenance order)

| NO | Time | Construction unit | Name of Maintenance Job |

| 1 | 2009.Feb—Mar | Riyadh Cement Company | REFRACTORY WORK |

| 2 | 2009.Feb | Riyadh Cement Company | Replacment of Cawl shell Kiln No.1 and Duct damper |

| 3 | 2009.May | Northern Region Cement Co. | Raw mill maintenance Job |

| 4 | 2009.June | Northern Region Cement Co. | REFRACTORY WORK |

| 5 | 2009.Dec | Riyadh Cement Company | Maintenance Job |

| 6 | 2010.Apr | Northern Region Cement Co. | REFRACTORY WORK |

| 7 | 2010.Jul | Riyadh Cement Company | Maintenance Job for Kiln 1 |

| 8 | 2011.May | Al Jouf Cement Company | Maintenance Job for Raw Mill |

| 9 | 2011.May | Al Jouf Cement Company | Maintenance Job for Kiln |

| 10 | 2011.May | Al Jouf Cement Company | Maintenance job of HV Cable |

| 11 | 2011.Aug | Saudi Cement Company | Maintenance job for SCC HOFUF Plant |

| 12 | 2011.Sep | Northern Region Cement Co. | Maintenance job for Cement Mill |

| 13 | 2011.Nov | Northern Region Cement Co. | CEMENT MILL 2 MAINTENANCE |

| 14 | 2011.DEC | Northern Region Cement Co. | REFRACTORY WORK |

| 15 | 2012.Jan | Northern Region Cement Co. | CEMENT MILL REDUCER MAINTENANCE |

| 16 | 2012.Feb | Northern Region Cement Co. | IKN ROLLER CRUSHER REPLACEMENT |

| 17 | 2012.Feb | Northern Region Cement Co. | Raw mill maintenance Job |

| 18 | 2012.Feb | Northern Region Cement Co. | Replacement of belts & buckets. |

| 19 | 2012.Mar | Northern Region Cement Co. | Major Maintenance jobs |

| 20 | 2012.Mar | Northern Region Cement Co. | replacement of kiln support roller |

| 21 | 2012 Dec | Riyadh Cement Company | REFRACTORY WORK |

| 22 | 2013.Mar | Northern Region Cement Co. | MILL MAINTENNACE Replacement of grinding Roller & Table segments & overhauling, bearings, seals & sealing rings replacement. |

| 23 | 2013.Oct | Derba Midroc Cement | Tertiary Air Duct Firebrick Restoration |

| 24 | 2013.Oct | Derba Midroc Cement | Debriking and rebricking of Kiln Lining48.8m Castable casting work 45.32T Scaffolfing work 300M3 |

| 25 | 2014.Mar | Northern Region Cement Co. | REPAIRING OF RAW MILL & EP DUCTS DISMANTLE & ASSEMBLY |

| 26 | 2014.Jul | City Cement Co. | Work order for Dismantling ,Removal,and Installation of out let tube in City Cement Ball Mill,CM-A of Diameter 5.0 Meters. |

| 27 | 2014.Nov | Derba Midroc Cement | High polymer engineering material installation |

| 28 | 2014.Mar | NAJRAN CEMENT COMPANY | Harfacing & Rebuilding To Normal Diameters For 04 Nos. Rolls in Two Roller Press as Per Standard Procedure |

| 28 | 2014.Nov | Derba Midroc Cement | Debriking and rebricking of Kiln Lining48.8m Castable casting work 45.32T Scaffolfing work 300M3 |

| 30 | 2014.Mar | Riyadh Cement Company | Modification of evacuating ALKALI dust bin |

| 31 | 2015.May | Northern Region Cement Co. | CEMENT PROCESS CONTROL COMPUTER R720 (沙特NRCC软件升级) |

| 32 | 2015.Feb | Yamama Cement Factory | KILN 7 FEBRUARY 2015 SHUTDOWN SUBCONTRACTED SERVICE ( MOBILE CRUSHER # 3) |

| 33 | 2015.Apr | Northern Region Cement Co. | REPLACEMENT OF KILN COLD SHELL |

| 34 | 2015.Apr | Yamama Cement Factory | MAINTENANCE, REPLACEMENT OF PARTS AND CLEANING OF KILN #3 EP DUST SYSTEM, AS PER ATTACHED SCOPE OF WORK Enquiry for Mill Head replacement job in CM 2. |

| 35 | 2015.Apr | Northern Region Cement Co. | Repairing work of raw mill in NRCC |

| 36 | 2015.Feb | Yamama Cement Factory | Replacement of Airslide Canvass from Silo 1 & 2 up to Feeding Bucket Elevator |

| 37 | 2015.Apr | Yamama Cement Factory | KILN 6 APRIL 2015 SHUTDOWN SUBCONTRACTED SERVICES ( Clinker Cooler Area) |

| 38 | 2015.Jul | Riyadh Cement Company | Mill Head replacement job in CM 2 |

| 39 | 2015.Jul | Northern Region Cement Co. |

Scraping/replacement of shoe bearings at outlet only of cement mill #02 |